Researchers at Tohoku University have developed a groundbreaking multi-material 3D printing technique using Laser Powder Bed Fusion (L-PBF) to create lightweight yet durable automotive components. By increasing laser scan speed, they suppressed brittle intermetallic compounds in steel-aluminum alloys, enabling the successful production of the world’s first 3D-printed full-scale suspension tower.

(Artist’s concept.)

Tohoku University developed a durable steel-aluminum alloy via 3D printing, overcoming brittleness challenges with advanced laser techniques, paving the way for innovative, lightweight automotive components.

Researchers at Tohoku University’s Institute for Materials Research and New Industry Creation Hatchery Center have achieved a significant breakthrough in multi-material 3D printing, showcasing its potential for manufacturing lightweight yet durable automobile components.

Metal 3D printing involves building objects layer by layer, binding metal layers together using heat. This technique offers remarkable precision, enabling the creation of unique, highly customizable shapes while minimizing material waste compared to traditional manufacturing processes.

A key advantage of 3D printing is the ability to produce “multi-material structures,” which combine different materials strategically to optimize a component’s performance. For instance, integrating aluminum with steel in automobile parts can significantly reduce weight while maintaining strength. These advantages have made advanced 3D printing techniques a focal point for researchers worldwide, as they hold great promise for innovation in manufacturing.

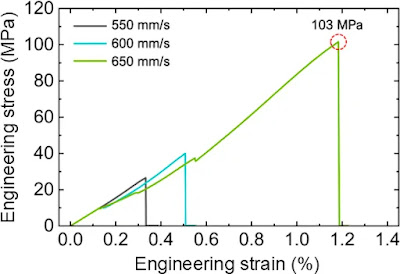

Steel/Al alloy interfaces obtained using L-PBF at different scan speeds. Credit: ©Kenta Yamanaka et al.However, this technique does come with some challenges.”Multi-materials are a hot topic in the field of additive manufacturing due to its process flexibility,” explains Associate Professor Kenta Yamanaka (Tohoku University), “However, a major challenge in practical implementation is that for certain metal combinations, such as steel and aluminum, brittle intermetallic compounds can be formed at the dissimilar metal interfaces. So, while the material is now lighter, it ends up being more brittle.”

Credit: ©Kenta Yamanaka et al.

Overcoming Challenges: Laser Powder Bed Fusion (L-PBF)

The goal of this study was to produce a steel-aluminum alloy that was lightweight but did not compromise on strength. To do so, the research team used Laser Powder Bed Fusion (L-PBF), one of the primary metal 3D printing technologies that employs a laser to selectively melt metal powders.

They discovered that increasing the scan speed of the laser significantly suppresses the formation of brittle intermetallic compounds (such as Al5Fe2 and Al13Fe4). They proposed that this higher scanning speed leads to something called non-equilibrium solidification, which minimizes solute partitioning that result in weak points in the material. The resulting product they created consequently demonstrated strong bonding interfaces.

Overcoming Challenges: Laser Powder Bed Fusion (L-PBF)

The goal of this study was to produce a steel-aluminum alloy that was lightweight but did not compromise on strength. To do so, the research team used Laser Powder Bed Fusion (L-PBF), one of the primary metal 3D printing technologies that employs a laser to selectively melt metal powders.

They discovered that increasing the scan speed of the laser significantly suppresses the formation of brittle intermetallic compounds (such as Al5Fe2 and Al13Fe4). They proposed that this higher scanning speed leads to something called non-equilibrium solidification, which minimizes solute partitioning that result in weak points in the material. The resulting product they created consequently demonstrated strong bonding interfaces.

Credit: ©Kenta Yamanaka et al.

“In other words, you can’t just slap two metals together and expect them to stick without a plan,” says Specially Appointed Assistant Professor Seungkyun Yim (Tohoku University),”We had to fully understand the in-situ alloying mechanism first.”

Based on this achievement, they successfully prototyped the world’s first full-scale automotive multi-material component (suspension tower) with a tailored geometry. The research group intends to apply these findings to other metal combinations where similar issues with bonding need improvement, which will allow for more broad applications.

“In other words, you can’t just slap two metals together and expect them to stick without a plan,” says Specially Appointed Assistant Professor Seungkyun Yim (Tohoku University),”We had to fully understand the in-situ alloying mechanism first.”

Based on this achievement, they successfully prototyped the world’s first full-scale automotive multi-material component (suspension tower) with a tailored geometry. The research group intends to apply these findings to other metal combinations where similar issues with bonding need improvement, which will allow for more broad applications.

Recommend this post and follow

The birth of modern Man

No comments:

Post a Comment

Stick to the subject, NO religion, or Party politics